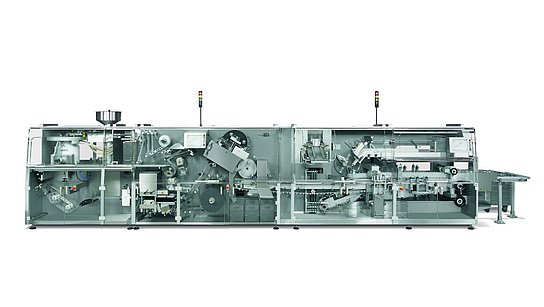

Safety is especially important when packaging highly potent drugs. The strategies and measures for protecting employees must go hand in hand with the design of the production facilities. At Körber, we are familiar with these challenges and can offer you intelligent packaging solutions based on decades of experience and individually tailored to your needs.

The spectrum is wide: it ranges from small batch sizes for personalized medicines, where high flexibility of the entire process chain is required, to highly sensitive, biological medicines, which require defined stable temperature and humidity conditions.

Occupational safety must also be ensured. For example, any contact between employees and highly potent materials must be prevented during the filling and packaging process. In some circumstances even a closed working environment (containment solution) is mandatory.

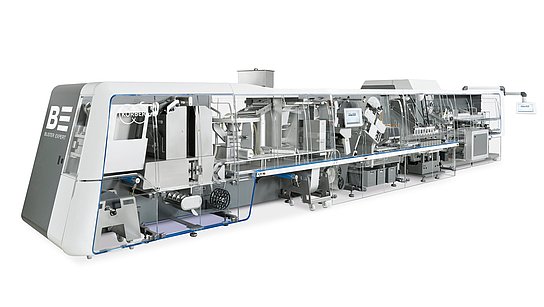

Körber's modular packaging solutions focus on digital solutions, automatic processes, flexible format changes, ease of operation and simple cleaning. As a result, they simplify the increasingly complex production process for pharmaceutical manufacturers, while at the same time master them safely and efficiently.