Future-proofing pharmaceutical inspection

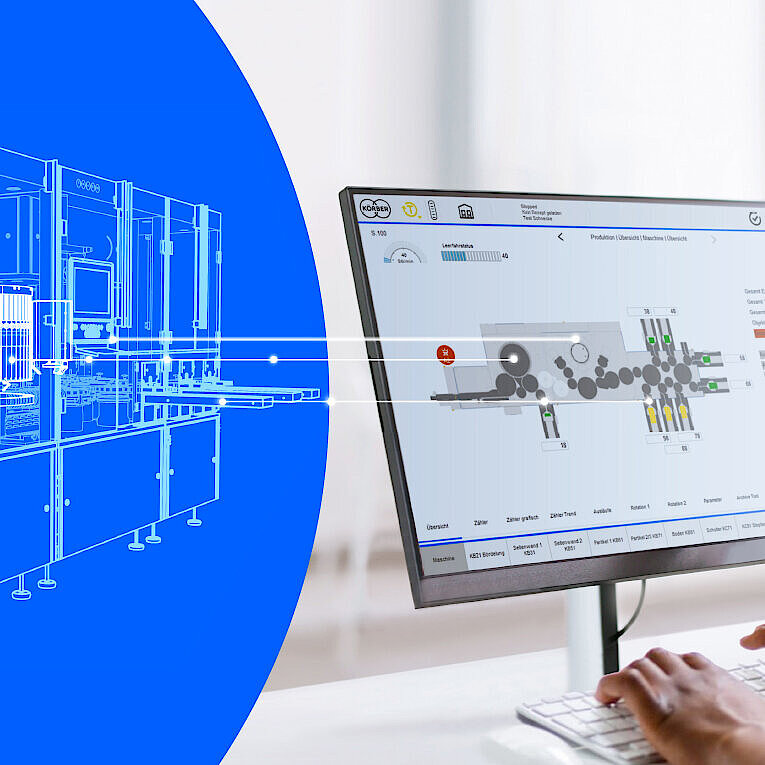

As a leading provider of inspection solutions for the pharma and biotech industries, Körber combines highly automated systems, AI-driven image processing, and modular platforms—now integrated into K.InspectionTwin.

Ralph Hugeneck, Senior Vice President of Körber’s Pharma business unit, emphasizes:

“With K.InspectionTwin, we are setting a clear course for the future of pharmaceutical inspection. Our vision is to leverage digital technologies to make processes more efficient, flexible, and sustainable. K.InspectionTwin directly impacts our customers’ ROI by increasing equipment availability, shortening development cycles, enabling faster product changeovers, and ensuring precise recipe development.”

K.InspectionTwin is hosted on regional servers within ISO-certified data centers operated by an AWS hyperscaler.

Following successful pilot projects, Körber is officially introducing K.InspectionTwin as part of its inspection portfolio. The solution is integrated into the Körber Ecosystem, combining the highest quality standards with a strong customer-centric approach. Beyond improving equipment availability and detection rates, K.InspectionTwin also contributes to greater sustainability in pharmaceutical production.