Are you looking for tailor-made, precise packaging solutions that can be integrated smoothly into your production processes? Look no further, at Körber we provide one-stop packaging service for your pharmaceutical products.

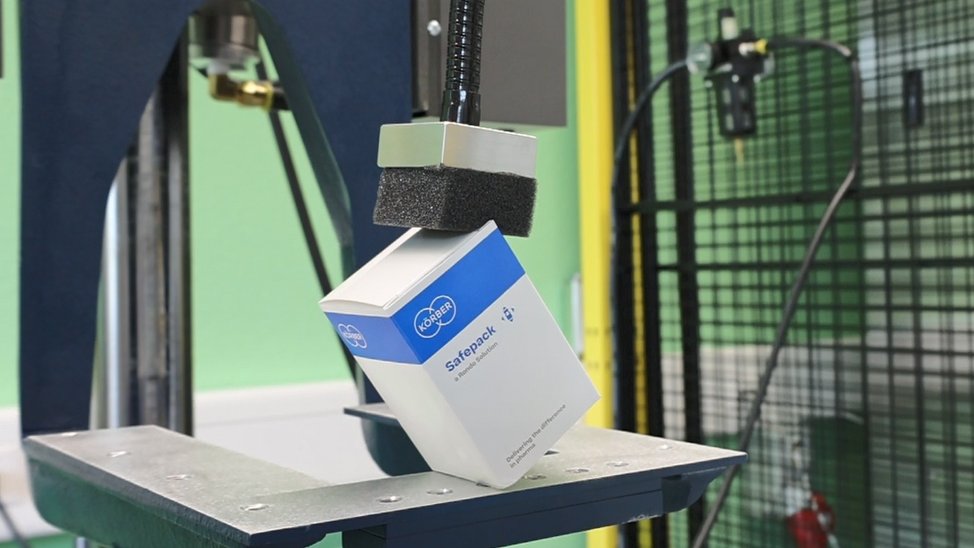

Along with their know-how and many years of experience in the industry, our Körber packaging experts provide you with a Packaging Qualification Service that enables you to revise secondary packaging for optimum product protection of the packaging materials already during their development through qualified pre-tests.

In addition to the development of pharmaceutically compliant secondary packaging, we offer validated pretests that comply with applicable standards and guidelines.