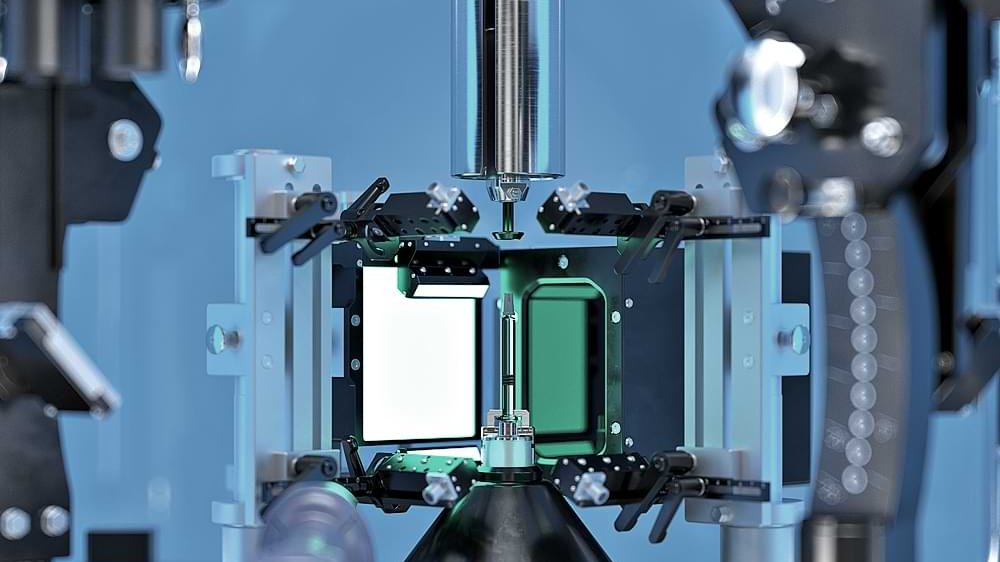

Check samples from your production visually on a handy tabletop unit directly on the production line or under production conditions conveniently in the laboratory. Or test various parameters of your automatic inspection in advance on a fully equipped inspection unit smaller than on one square meter – without interrupting your ongoing production. For the manual inspection of your products, we offer you ergonomic support as a handy tabletop unit or height-adjustable inspection booth, designed in accordance with USP1790.