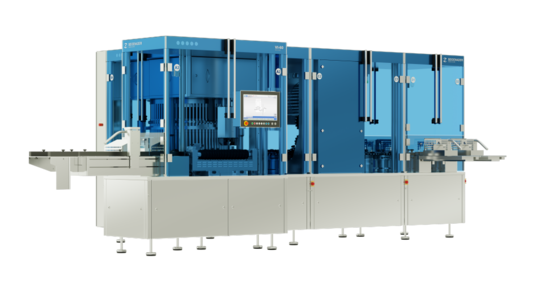

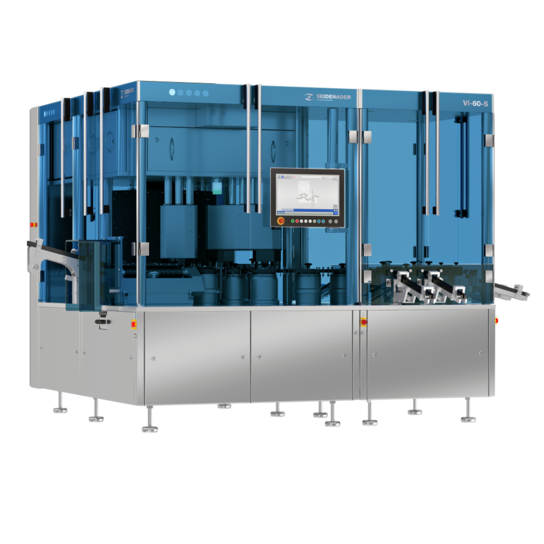

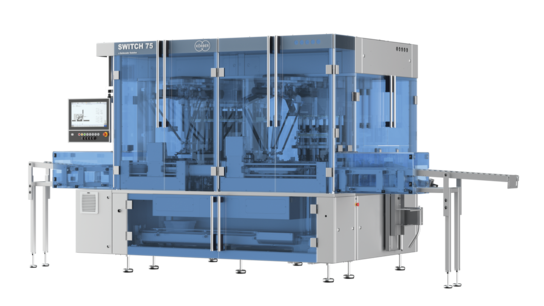

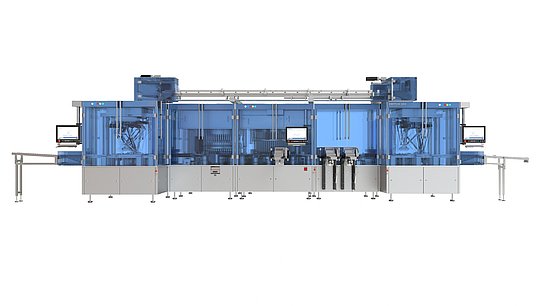

UpsideDown: Special handling for special products

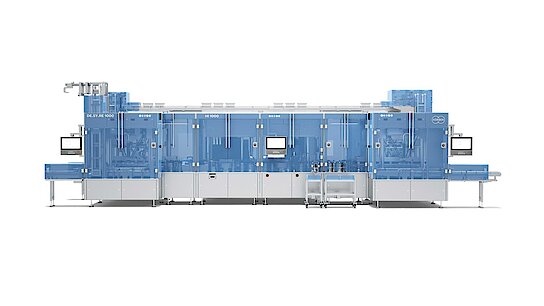

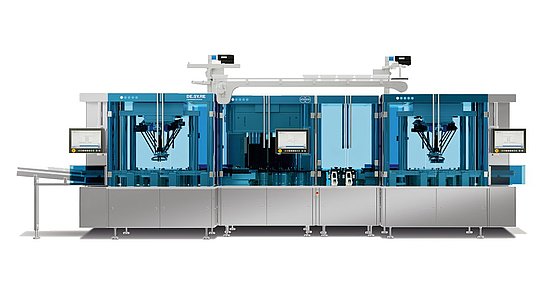

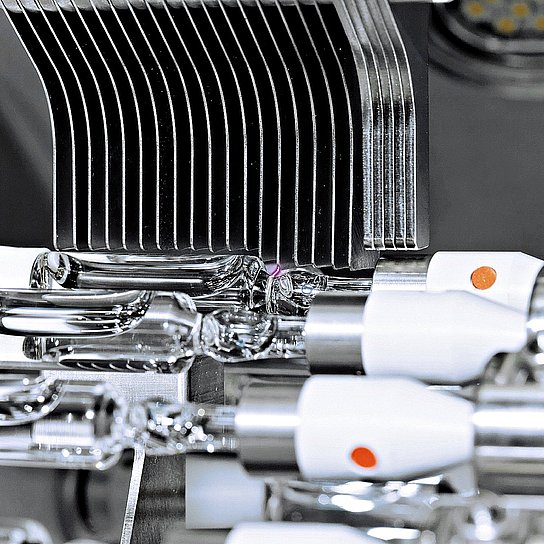

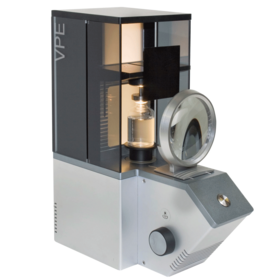

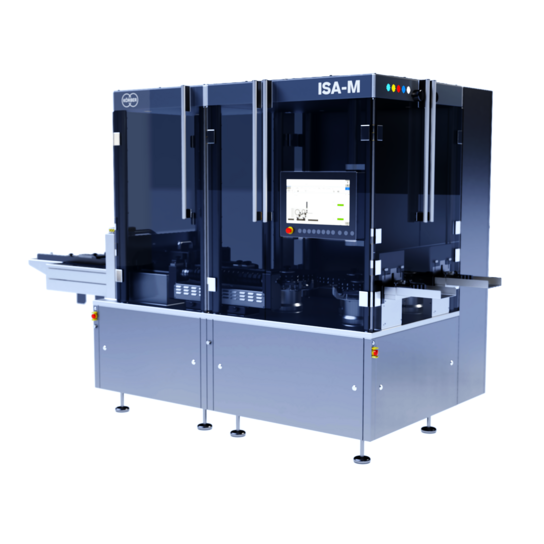

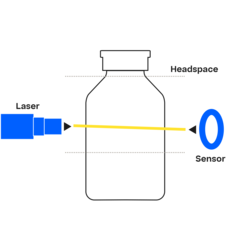

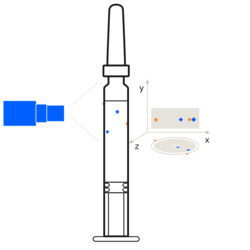

Machine module for leak testing of ampules containing higher viscosity liquid, and of low filled vials.

Also designed for stopper and shoulder inspection when the product needs to be turned upside down to eliminate droplets that lead to false rejects.