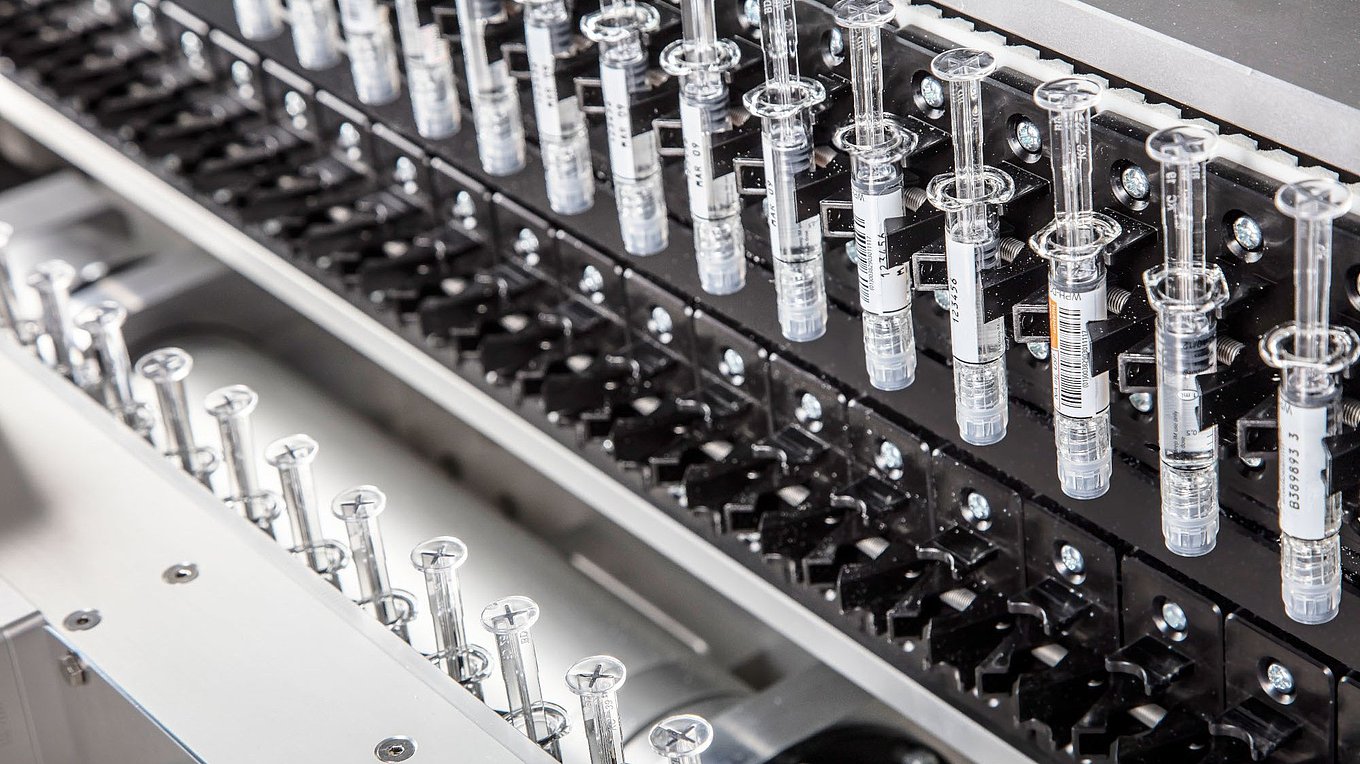

Optimize your line efficiency with accumulation between the upstream and downstream machines. Our accumulators let you decouple two machines, meaning you can run different equipment at varying speeds while still maintaining balance in the event of upstream or downstream stoppages.

Boost your secondary automation processes with our blister accumulator/sleever. The machine features inline blister accumulation, and you can accommodate a large range of blister sizes, plus have the option of secondary sleeving.