Solutions

Software solutions

Handling systems

Inspection

Packaging machines

Packaging solutions

Consulting

Services

Top-class handling Systems

With complete handling systems for pharmaceutical and medical products, Körber delivers automated, flexible and secure product transport and tray systems. While you focus on your production, our ecosystem approach ensures that all parts, components, hardware and software operate harmoniously and perform at the highest level.

Transport solutions Accumulation solutions Nest and tray handling Customized handling systems Line integration

Transport solutions

Our product transport solutions offer you efficient overhead conveying, lane management, peak-buffer systems, and complete non-contact systems. They are perfectly matched to your requirements.

Accumulation solutions

Our accumulators are the perfect addition to any solution, creating a system that will continue to operate if a problem should arise on upstream or downstream equipment. The products are taken from the outfeed conveyor of the upstream machine and transferred to the infeed conveyor of the downstream machine. In the event of a standstill, the product is accumulated into the system or correspondingly reintroduced from it. Our systems provide line optimization, control of products, and reduce the potential for jams. We have a variety of accumulators to fit your business needs.

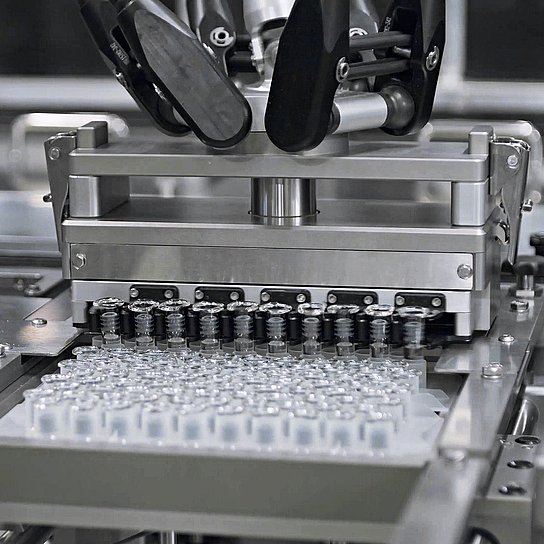

Nest and tray handling

Thanks to their seamless integration into your upstream and downstream systems, our fully automated systems, which are designed for nest and tray loading and unloading of e.g. insulin syringes, offer you added value.

Customized handling systems

Our custom handling solutions meet your specific requirements. We pride ourselves on the ability to design a system that can be adapted to meet any need. Through innovative engineering and the latest designs, we are committed to transforming any solution to create a custom high-performance line to fit your specifications.

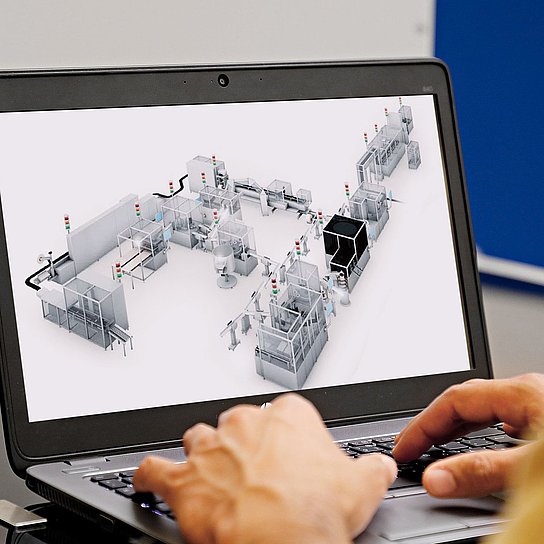

Line integration

Our expertise is not limited to our transport solutions. We can create an entire transport concept covering your complete line to ensure we meet all of your product handling needs. Through extensive design integration, our experts have created holistic solutions for the most challenging projects. Our sophisticated, complete and flexible systems generate a cohesive design concept through cooperative partnerships with our customers.

About us

We are your contact when it has to do with pharmaceutical products. As a leading system supplier, we advise you on everything from development through manufacturing and inspection all the way to the packaging of your products.