Boost the reliability and efficiency of your production process by conducting quality control checks before the final inspection takes place. Our integrable inspection systems allow you to detect defects long before they cause any damage.

Inspection

Boost the reliability and efficiency of your production process by conducting quality control checks before the final inspection takes place. Our integrable inspection systems allow you to detect defects long before they cause any damage.

Minimized machine downtimes and fewer rejects save time and money

Whether in a cleanroom or under an isolator, our inspection system is suitable for every filling line. It is gas-tight, VHP-proof, and optimized for laminar flow

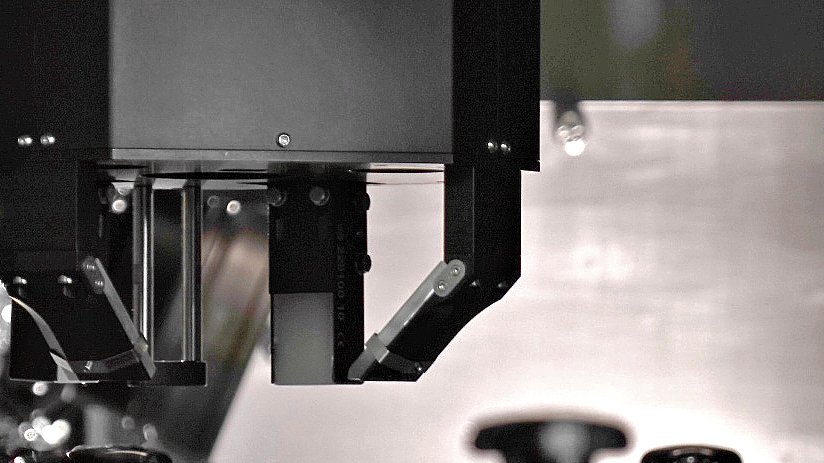

A special optical unit and a recipe-controlled positioning of the camera optimize fault identification

The empty container inspection system from our Seidenader Solutions allows for screening your containers for particles, fragments, inclusions, scratches, cracks, and incorrect dimensions before filling them with expensive product.

We integrate our inspection stations into your filling machines under isolator and cleanroom conditions in a space-saving manner. Sort out defective containers before filling and avoid unnecessary rejects of valuable medications or expensive machine downtime.

A closed housing protects it securely against moisture, dust, and incorrect operation

Whether in a cleanroom or under an isolator, our inspection system is suitable for every filling line. It is gas-tight, VHP-proof, and optimized for laminar flow

The raised stopper inspection from our Seidenader Solutions enables you to check if the stopper is present and whether it is fitted properly for the following process step.

Depending on the contents and the production process, a container should either be completely sealed and the stopper fully inserted, as is usually the case at the end of a filling process, or the closure has to remain permeable and the stopper only inserted halfway, for example, as is necessary for lyophilization.

Safely protected against moisture, dust and operating errors by a closed housing

Whether in a cleanroom or under an isolator, our inspection system is suitable for any filling line. It is gas-tight, VHP-proof, and optimized for laminar flow

With the crimp cap inspection from our Seidenader Solutions, you check the crimp and cap of vials for cosmetic and functional defects.

Correct capping and crimping of pharmaceutical containers is critical to the safety and quality of the product. That’s because closures often also are used for dosing or administering the product. By inspecting directly after crimping or cap placement, you ensure that defects such as dents, scratches or damaged seals as well as inaccurate positioning, wrong color or the absence of the flip-off cap are already detected during production, thus enabling you to quickly eliminate possible faults within the process.

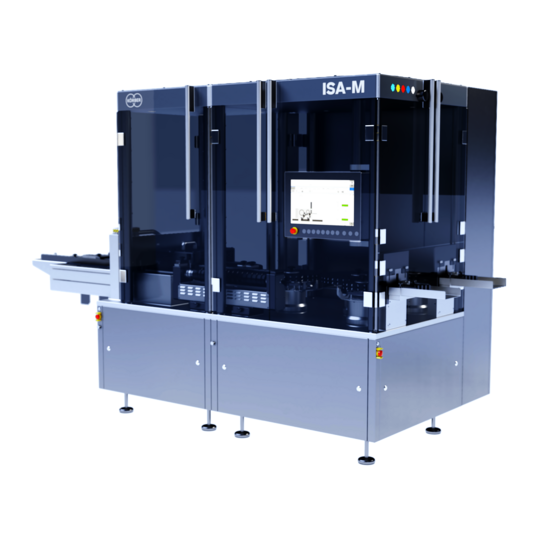

For cosmetic inspection at any stage of your production process: ISA-M

Adding quality control of pharmaceutical products to a process prior to the end-of-line inspection is often a challenge. If there is no possibility to integrate a camera system into your filling or capping equipment, we offer ISA-M as stand-alone solution to inspect your product at any step during production.

Inspect products already during production at up to 600 containers per minute prior to final inspection and detect emerging defects in your production long before they become major incidents that lead to costly profit losses.

Technical details of our compact stand-alone solution for in-process cosmetic defect inspection – up to 600 containers/min.