Solutions

Software solutions

Handling systems

Inspection

Packaging machines

Packaging solutions

Consulting

Services

Inspection solutions for top quality requirements

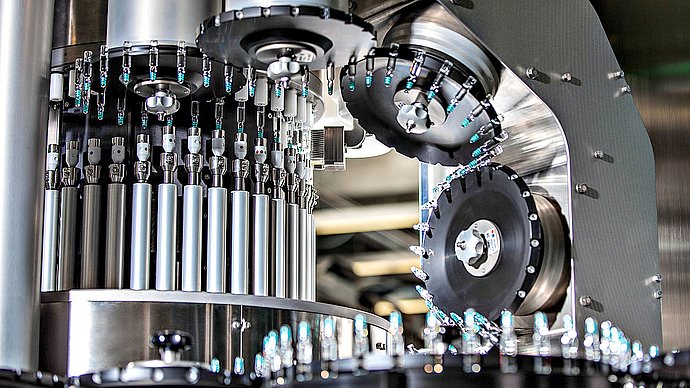

Whether pharmaceutical or biotech products in liquid, highly viscous or freeze-dried form; Whether syringes, vials, ampules or cartridges: We know the stringent requirements that sensitive products and fragile containers place on transport systems as well as the demands that our inspection technologies pose for handling. Our connected solutions provide the optimal answer to all your inspection requirements, allowing you as a manufacturer to ensure that only flawless products leave your facilities.

Machine finderAutomatic inspectionSemi-automatic inspectionLab equipmentIn-process controlLine integration

More than the sum of its parts

Our high-performance machines with state-of-the-art inspection technology for the most demanding requirements in the pharmaceutical and biotech industry.

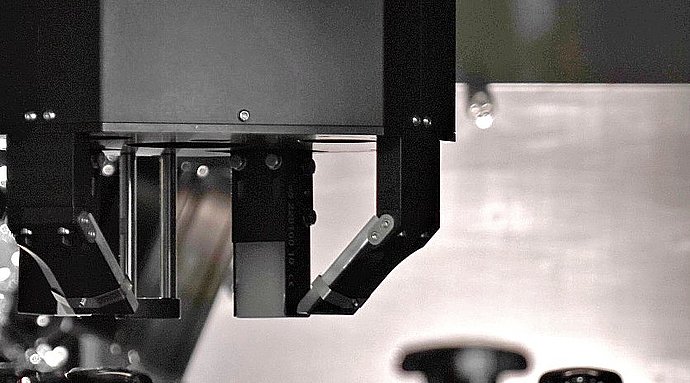

Each of our inspection machines from Seidenader Solutions combines three core competencies: The inspection forms the heart of the machine. Handling is the hand, while the control is the brain, which ensures that all components interact smoothly. The result is more than the sum of its parts: Innovative inspection solutions — every challenge can be solved.

One idea, endless possibilities

One idea, endless possibilities

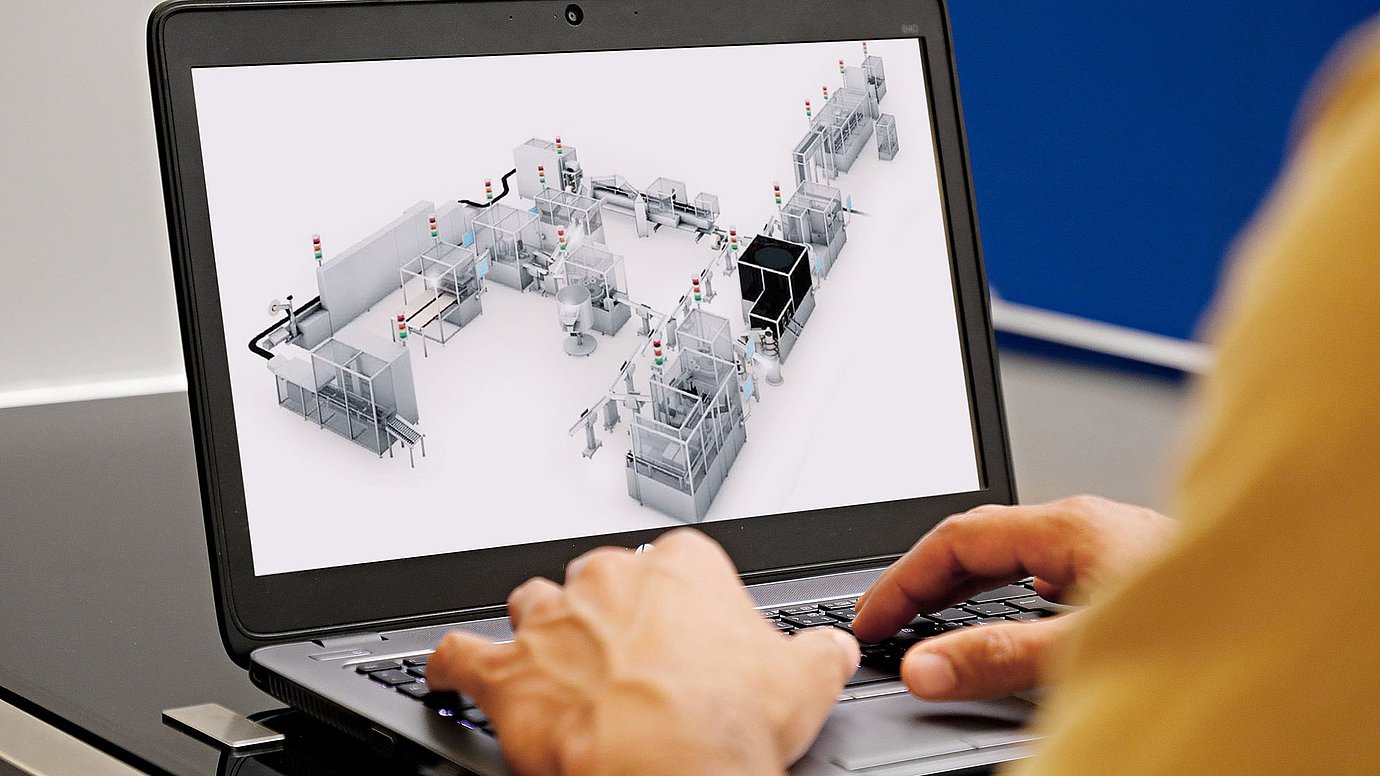

Our Seidenader Solutions are characterized by modularity and flexibility that leave nothing to be desired - both within a machine and across the entire product portfolio.

About us

We are your contact when it has to do with pharmaceutical products. As a leading system supplier, we advise you on everything from development through manufacturing and inspection all the way to the packaging of your products.