The demand for personalized medication is growing, as is the desire to bring products quickly to market after successful clinical trials. Small batch production has become a necessity for manufacturers of medical and pharmaceutical products. For many medicines, batch sizes are decreasing, but the demands on packaging are increasing: Artwork, label and package inserts have to be adapted to country-specific requirements, and counterfeit protection, tamper protection and full traceability must be fulfilled.

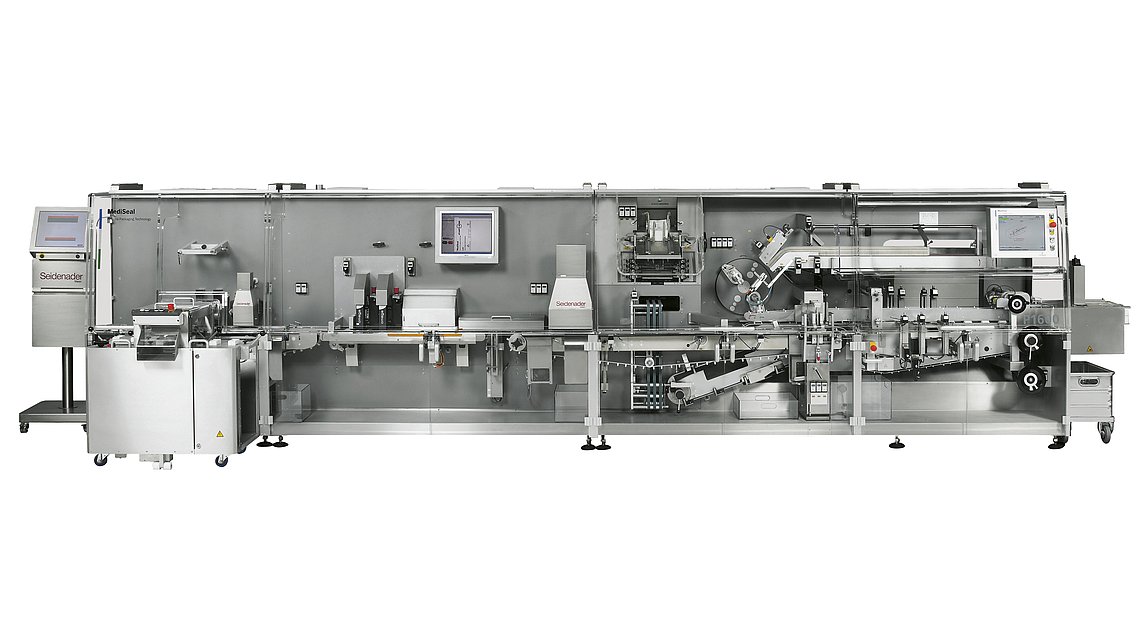

Körber's modular packaging systems are particularly suitable for pharmaceutical manufacturers of small batches - right down to individual units. Semi- or fully-automatic production lines for parenteral products can be set up embedded in an intelligent software structure. Optimised pack sizes can be designed as top-load or sideload variants.