In order to authenticate pharmaceuticals, make use of our offline serialization service to ensure better patient protection.

Concerning the serialization of pharmaceuticals, pharmaceutical companies globally face significant challenges fulfilling Directive 2011/62/EU. This is especially true of data handling and incorporation of additional devices and functions into existing packaging lines.

When combined with cleverly designed data flow concepts, offline solutions, in which secondary packaging is serialized directly by the folding box producer, are a secure, flexible, and immediately available alternative to inline serialization.

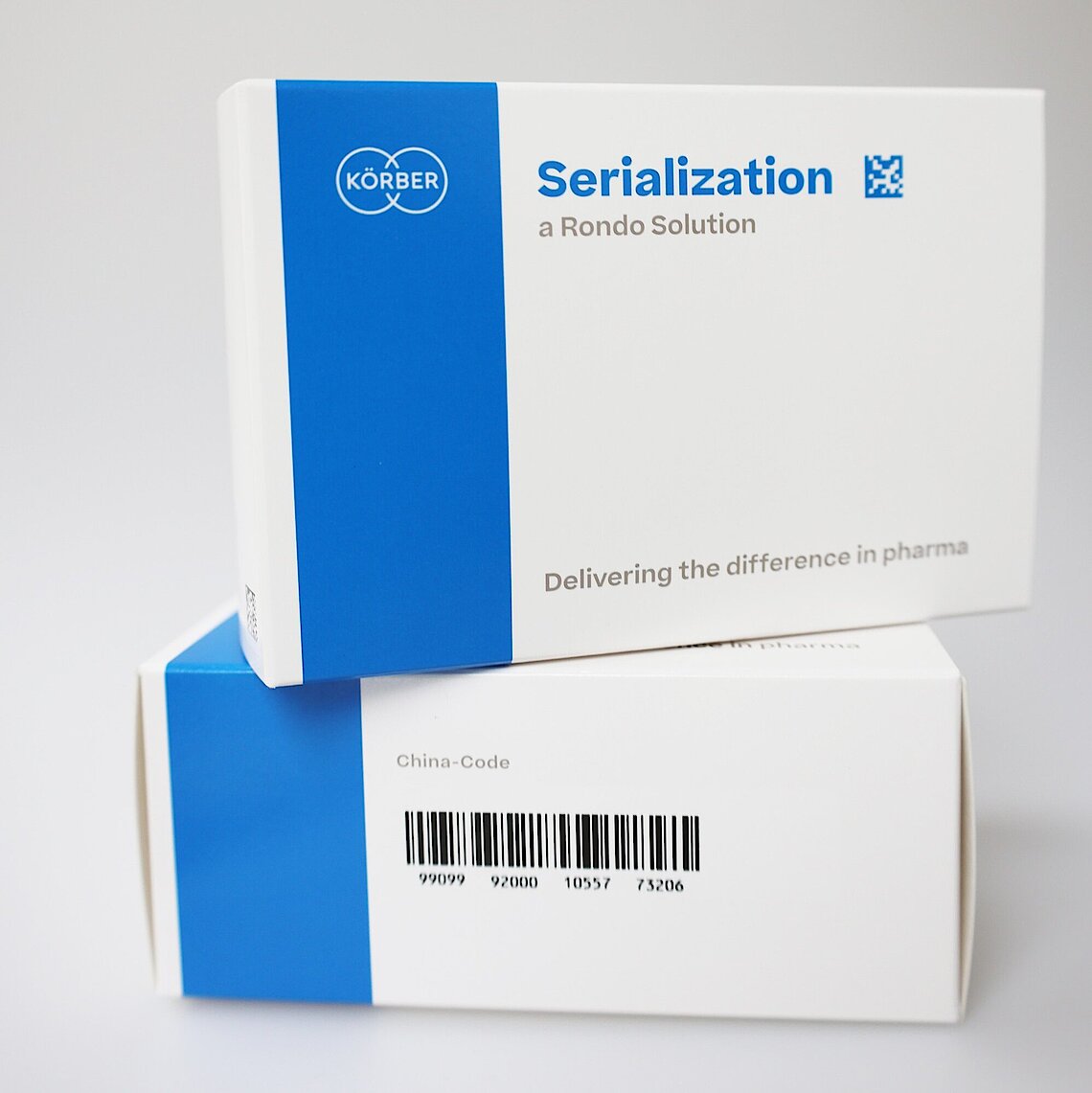

In this case, the serialization numbers are provided by a track and trace solution such as Werum PAS-X Track & Trace and printed directly onto the packaging by the manufacturer. The pre-printed packaging is then delivered to the customer, where the code is read and reported back to the track and trace system.

Packaging lines remain continuously efficient if printing technology, cameras, and ejection systems don’t have to be integrated. The use of unique code software prevents duplicates, particularly in disruptive or special situations, and ensures consistent serialization results. The folding box producer is responsible for validating the printing process.

Advantages

- Secure management of serial numbers and reliable accounting of each product

- Printing of all common code formats such as C128 barcode (China code) and 2D DataMatrix (GS1) code

- No additional investment in existing packaging lines

- No additional effort for line clearance during the packaging process

- Access to cutting-edge printing processes with high-contrast printing appearance for optimal optical character recognition

- Free positioning of the codes possible within the entire print area of a folding box

- Pharmaceutical-conform data flow concepts and processes

- Access to additional services such as tamper evidence features and special security functions