Unsere Lösungen

Software

Transportsysteme

Inspektion

Verpackungsmaschinen

Verpackungslösungen

Beratung

Services

Ticketsystem für Machine Services

Inspektionslösungen für höchste Qualität

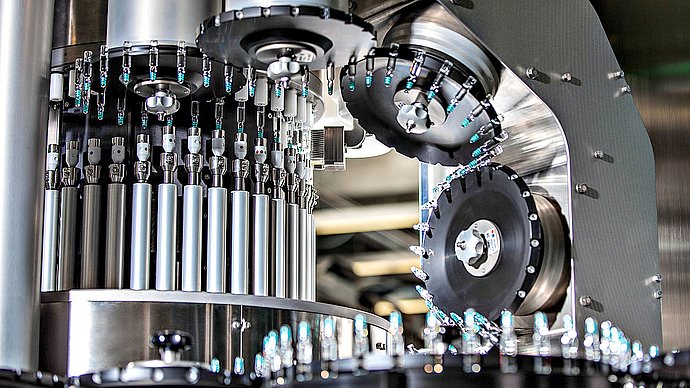

Ob Pharma- oder Biotechprodukte, flüssig, hochviskos oder gefriergetrocknet, ob Spritzen, Vials, Ampullen oder Karpulen: Wir kennen die hohen Anforderungen, die empfindliche Produkte und zerbrechliche Behälter an Transportsysteme stellen – und welche Anforderungen unserer Inspektionstechnologien zu berücksichtigen sind. Unsere vernetzten Lösungen bieten die optimale Antwort auf alle Ihre Inspektionsanforderungen. So können Sie als Hersteller sicherstellen, dass nur einwandfreie Produkte Ihr Werk verlassen.

Maschinen-FinderAutomatische InspektionHalbautomatische InspektionLaborequipmentInprozesskontrolleLinienintegration

Mehr als die Summe seiner Teile

Unsere Hochleistungsmaschinen mit modernster Inspektionstechnologie für die höchsten Ansprüche der Pharma- und Biotechindustrie.

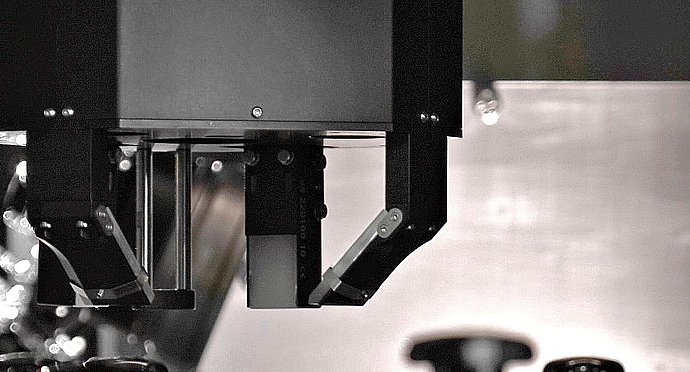

In jeder Inspektionsmaschine unserer Seidenader Solutions vereinen sich drei Kernkompetenzen: Die Inspektion, sie bildet das Herz einer Maschine, das Handling ist die Hand – und die Steuerung das Hirn, das dafür sorgt, dass alle Komponenten perfekt zusammenarbeiten. Das Ergebnis ist mehr als die Summe seiner Teile: Innovative Inspektionslösungen – jede Herausforderung ist lösbar.

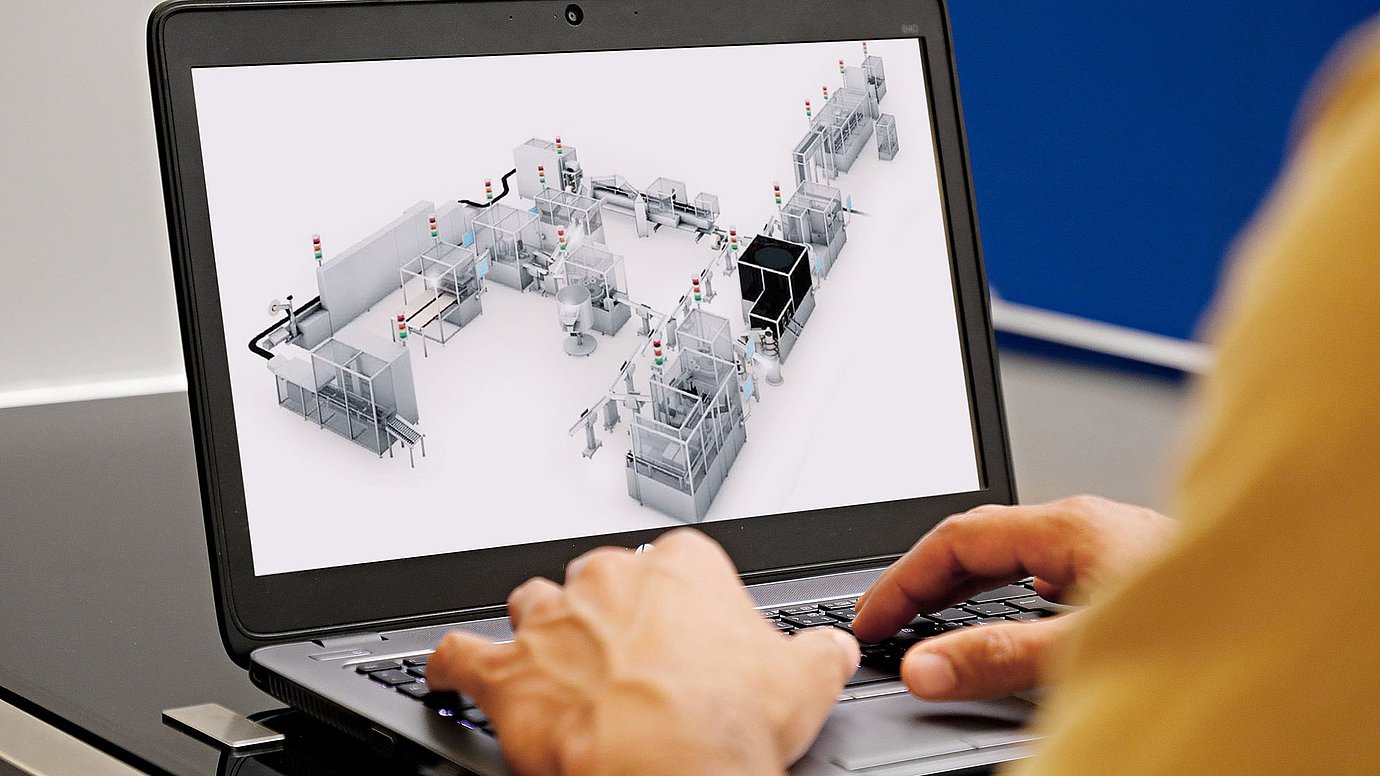

Eine Idee, unendliche Möglichkeiten

Eine Idee, unendliche Möglichkeiten

Unsere Seidenader Solutions zeichnen sich aus durch Modularität und Flexibilität, die keine Wünsche offen lassen – sowohl innerhalb einer Maschine als auch über das gesamte Produktportfolio hinweg.

Unendlich viele Anwendungen, eine Software

Unendlich viele Anwendungen, eine Software

Die Module und Maschinen werden alle über eine einheitliche Software gesteuert und über ein durchgängiges HMI bedient. Und unser Motto, „Konfigurieren statt Programmieren“, ermöglicht uns, neue Maschinen, Upgrades und Retrofits unkompliziert an Ihre Wünsche und Anforderungen anzupassen.

Über uns

Wir von Körber im Geschäftsfeld Pharma sind Ihr Ansprechpartner, wenn es um pharmazeutische Produkte geht. Als führender Systemanbieter beraten wir unsere Kunden von der Entwicklung über die Herstellung bis zur Inspektion und Verpackung ihrer Produkte.