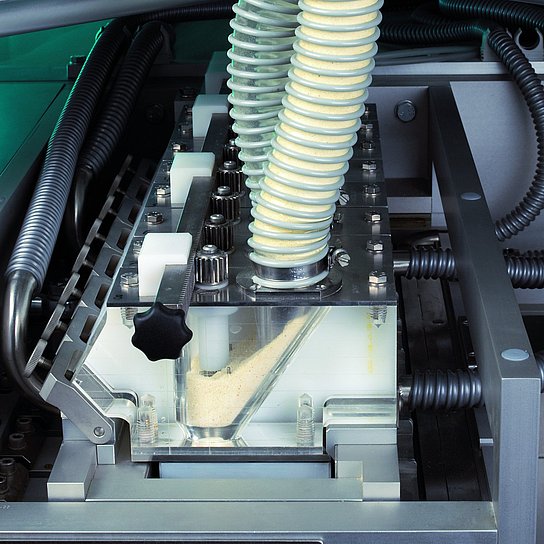

As a full-service supplier of packaging solutions, Körber offers a broad range of add-on products. Our dosing and feed systems can be perfectly integrated into your existing product lines for secondary packaging or used to optimally link the primary and the secondary packaging. Customer-focused and solution-oriented, we work on holistic solutions for today's and tomorrow's challenges.