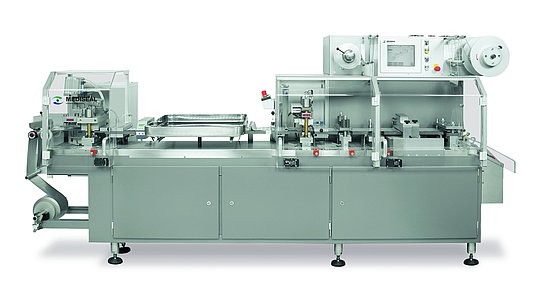

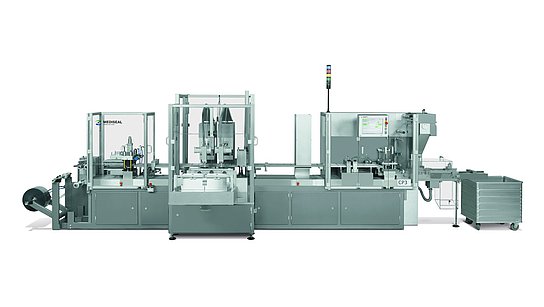

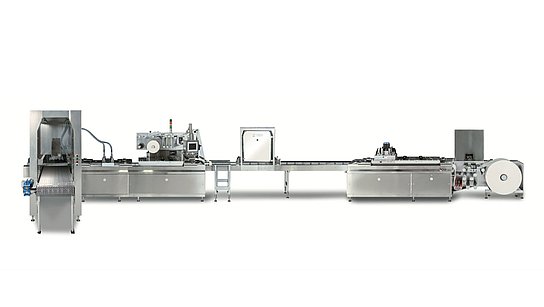

When it comes to individually developed, future-proof and versatile blister lines for medical products, Körber is the right partner for you. With our packaging solutions, we support you at all times in meeting the constantly changing requirements of a demanding industry. This also applies to newly added formats or products. Designed for nearly one hundred percent technical runtime and efficiency, we offer you flexible solutions that allow you to respond to changes immediately.