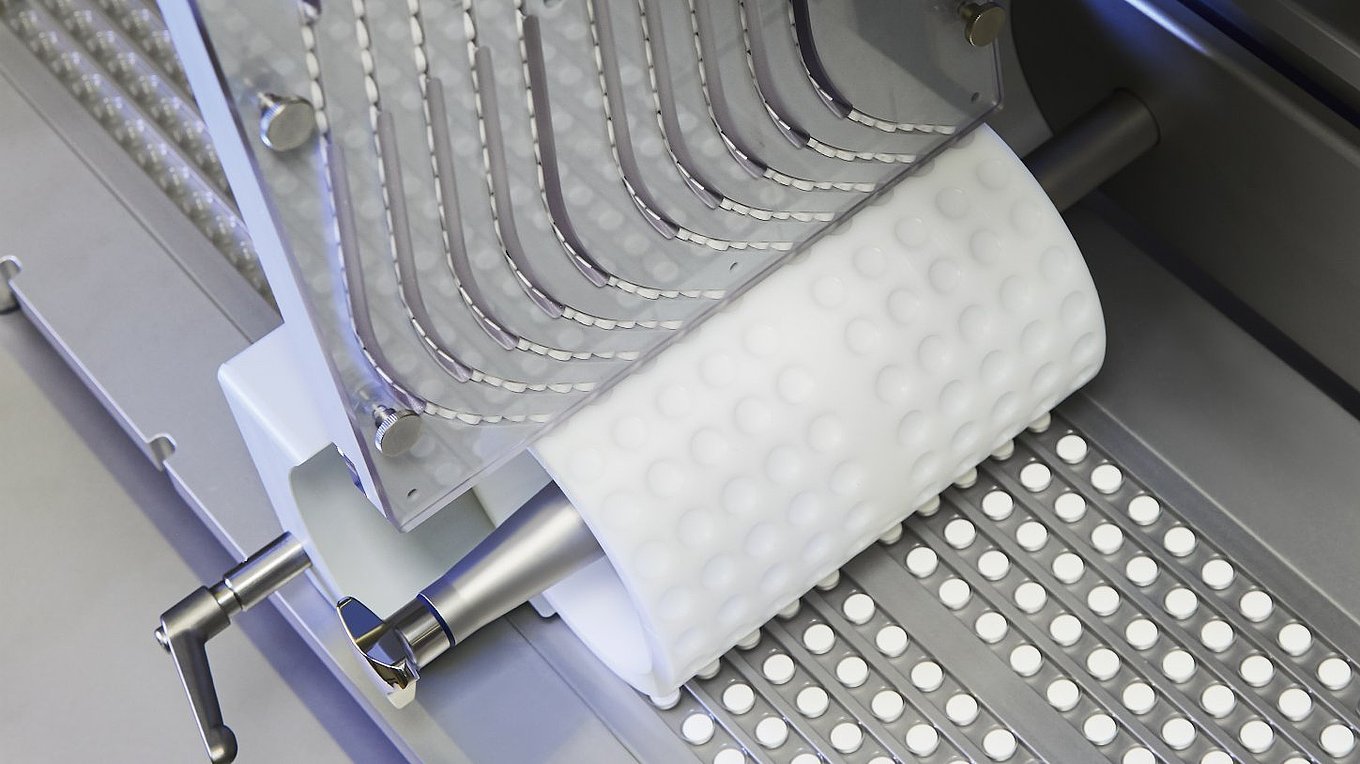

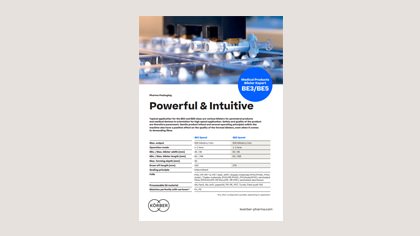

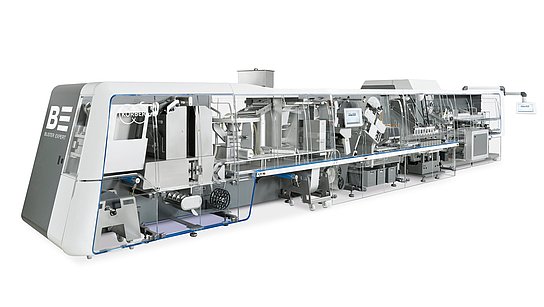

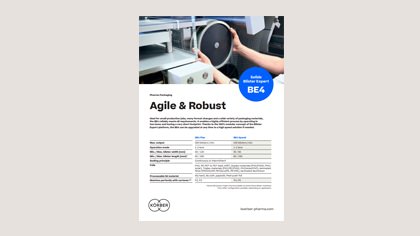

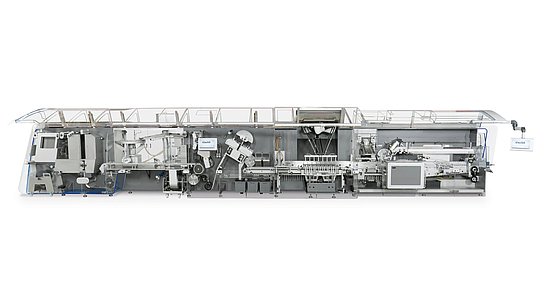

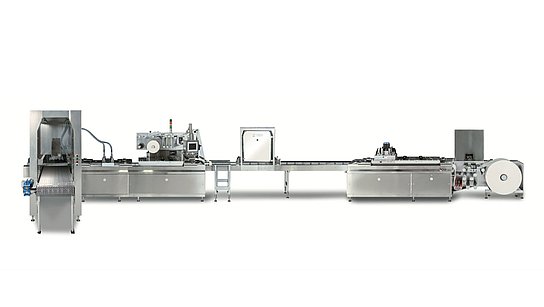

At well over 60 percent, tablets and capsules are the most common dosage form for medications – and will remain so in the future. With blister machines from Körber, you can increase the efficiency of your solid dose production. On our Blister Expert platform, we use a smartphone-like user interface that provides many customer-specific functions. When optimizing your processes, we keep an eye on the overall performance of your equipment throughout its entire life cycle. This allows us to achieve real breakthroughs in productivity through the individual integration of our modular machine concept.