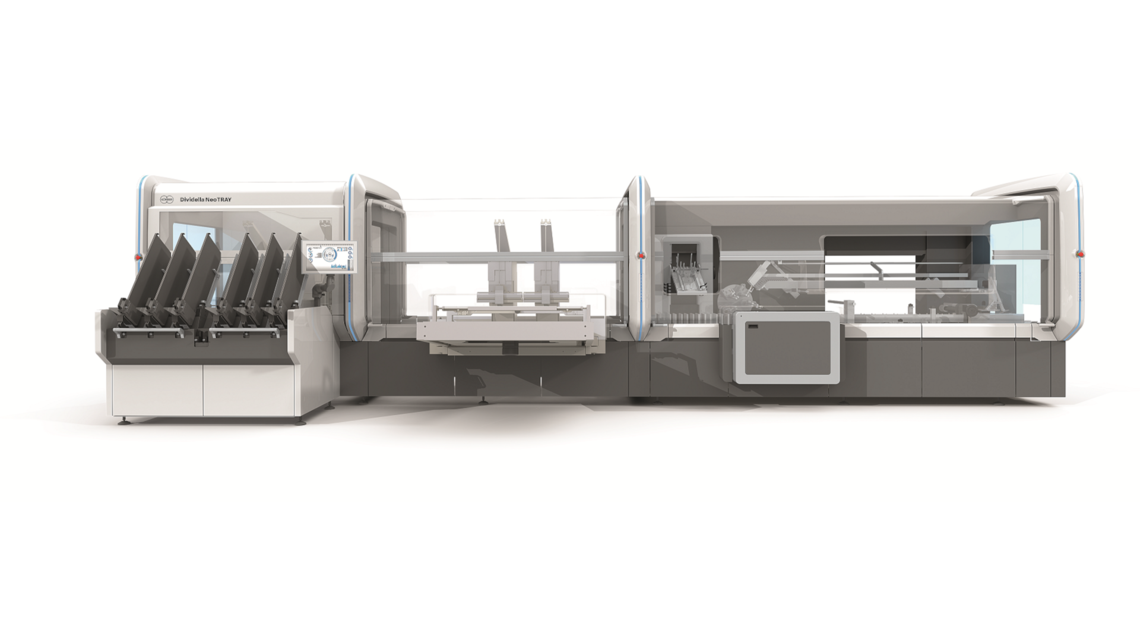

This high-speed system is suitable for a wide range of applications: Parenteral drugs in the form of vials, syringes, injectors, pens, ampoules, cartridges, inhalators, nasalsprays, and other systems can be securely packed in large volumes.

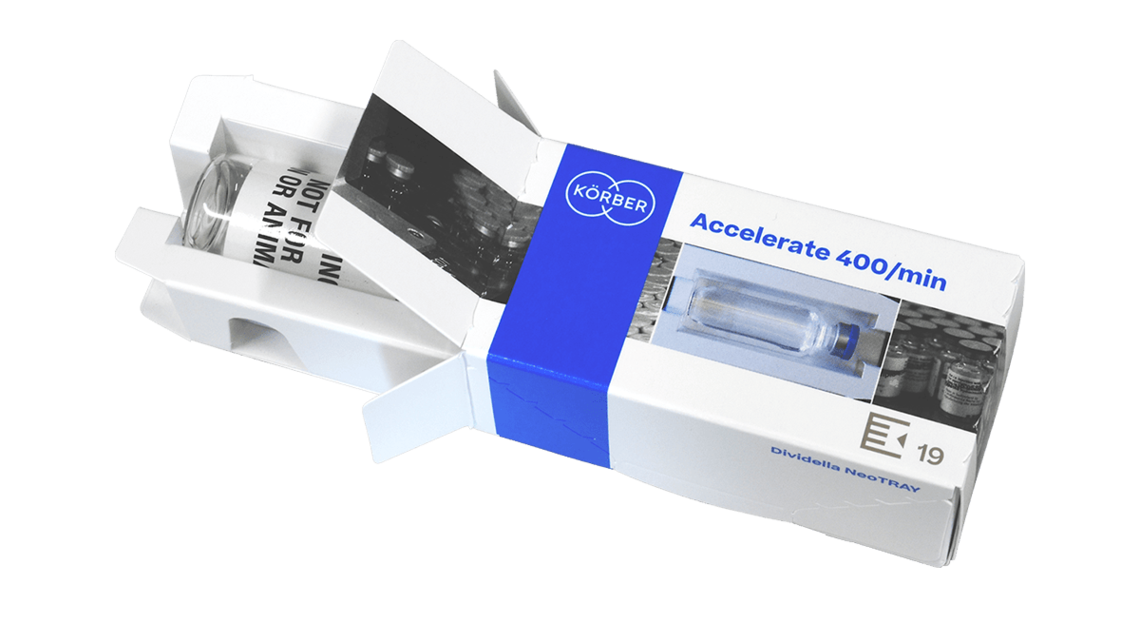

As a manufacturer, you respond to new requirements at any time and serve the market. With its high speed, the NeoTRAY from Dividella Solutions can process up to 400 individual products or multipacks per minute and reliably adapts to a wide range of formats. In addition, the machine uses the proven advantages of mono-material and produces the packaging from 100 per cent economical and sustainable cardboard.