At Körber, we package pharmaceutical products more than safely: beyond that our packaging solutions are sustainable, environmentally conscious and patient-friendly.

Your benefits:

- Flat cardboard and partition blanks – printable on both sides

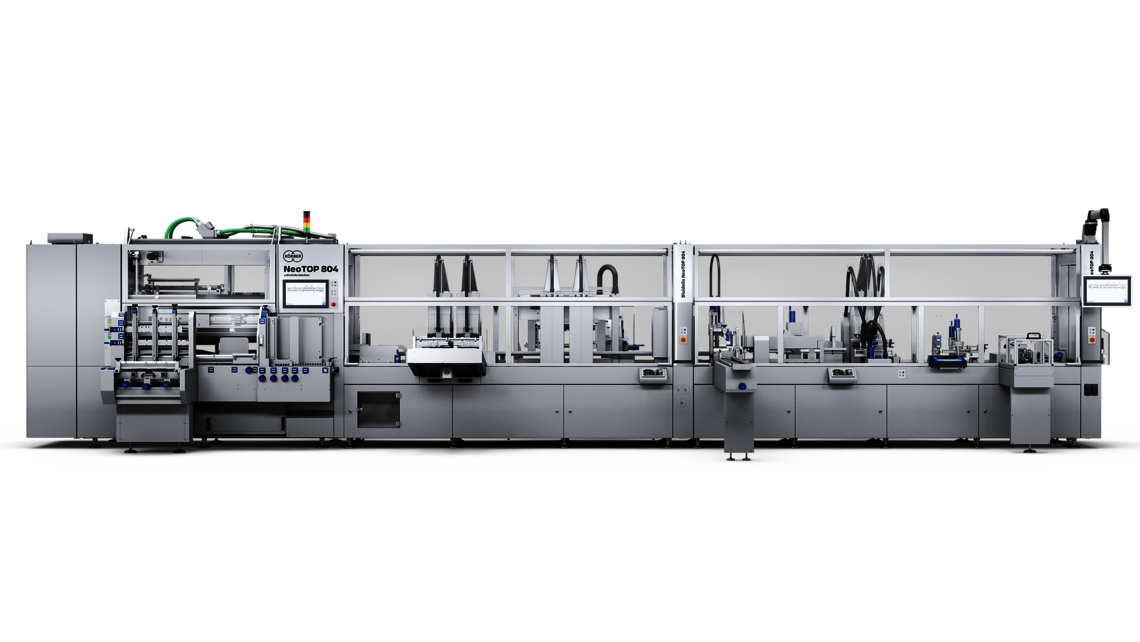

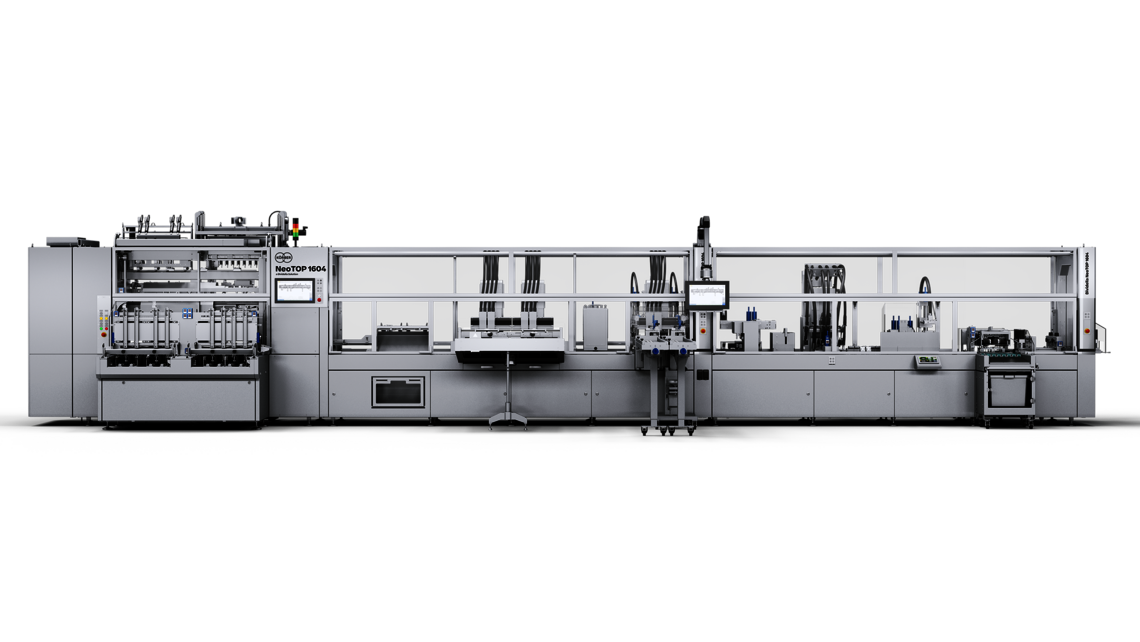

- Secure automated erecting and gluing

- Secure product insertion process (100% verification after insertion)

Over the entire manufacturing and logistics process, this results in concrete advantages for you as a manufacturer of parenterals as well as your end customers, which positively influence both your Total Cost of Ownership (TCO) and your Total Cost of Package (TCP).