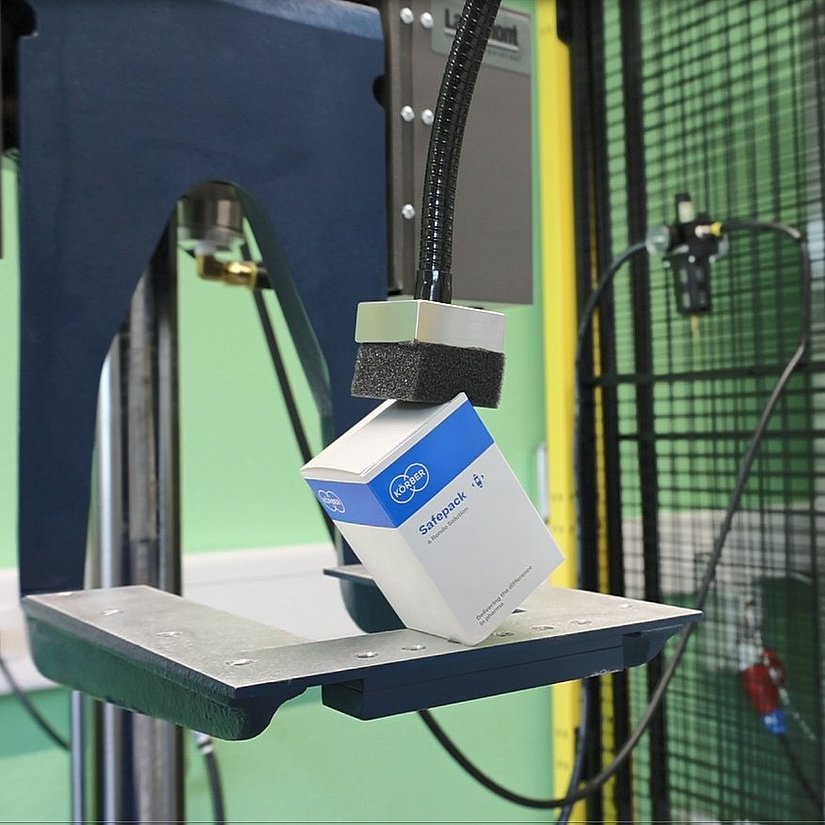

On top of the already high expectations placed on the pharmaceutical industry, there are also ambitious environmental sustainability goals. Körber is committed to addressing the expectations of diverse economic, political and social stakeholders. As a solution provider for the pharmaceutical industry, Körber has been gearing its packaging solutions towards saving resources and is already using alternative materials that reduce raw inputs and emissions. Thanks to stringent qualification processes, these materials do not compromise on functional aspects such as breakage prevention and product protection.

With many of the secondary packaging products that Körber develops and manufactures for its customers, plastic elements are increasingly giving way to paper inlays and paper fiber trays. These materials require less energy to produce than plastic and as a rule are 100% recyclable.